Email Us

info@alsholasafety.ae

info@alsholasafety.ae

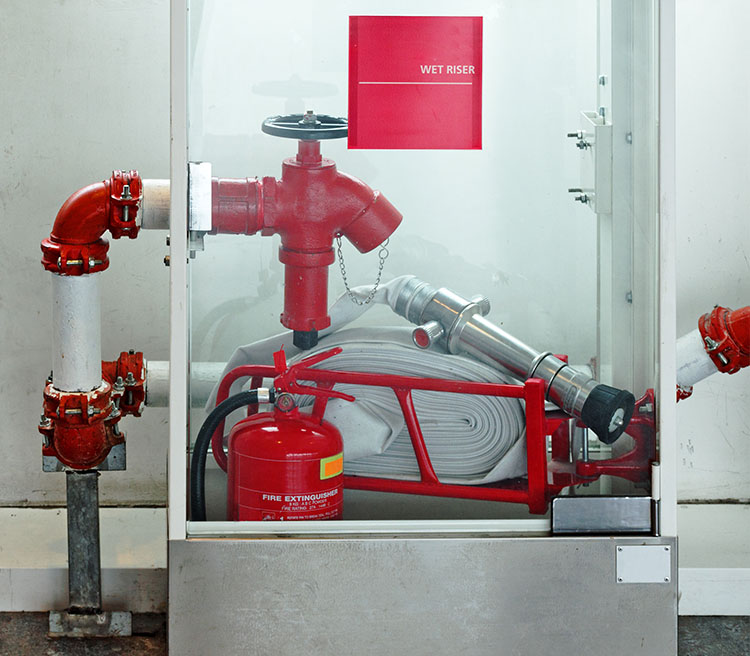

Our extensive expertise covers all the fire and life safety products listed in this section. We also have a dedicated team of fire protection engineers that are ready to provide expert advice on all aspects of your project. From initial planning to design, installation, and commissioning, we can help you choose the right combination of products for your needs.